Redefining Performance for Rock Breakers and Post Drivers

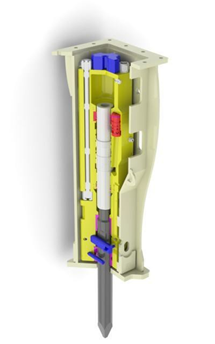

Thor employs an advanced piston-driven mechanism, powered by the renowned SB Power Cell that has dominated the industry for over 50 years. Operating at a nitrogen gas pressure of 16.5 bar, this mechanism delivers unparalleled impact Joules.

As hydraulic oil flows from the host machine into Thor’s power cell, it propels the piston within a nitrogen gas chamber. This hydraulic-nitrogen synergy sets the stage for generating substantial impact force. The pressurised hydraulic oil acts as the driving force, propelling the piston downward. This swift motion compresses the nitrogen gas, storing potential energy.

Upon reaching peak pressure, the hydraulic valve opens, triggering a controlled impact as the hydraulic oil is released. This dynamic process harnesses both hydraulic pressure and the stored compressed nitrogen energy. This energy combination propels the piston onto the rock chisel or post tool with formidable blows of impact Joules. Consequently, a sequence of precisely controlled impacts ensues, effectively driving the rock chisel or post tool with optimum force and accuracy. This capability ensures efficient material breakage or installation. The dual-source energy release equips Thor’s rock breakers and post drivers to adeptly adapt to diverse operational demands.

The integration of hydraulic flow control confers a significant advantage. The host machine’s operator can dictate the driver’s speed with precision by regulating the hydraulic flow. By adjusting the hydraulic flow rate, operators can either expedite or moderate the driving action. This adaptability optimally suits various tasks and materials. This level of control empowers operators to tailor the impact intensity to match job-specific requirements, thereby enhancing both operational efficiency and precision.

Minimal Moving Internal Parts – Simplifying Maintenance

THOR’s design philosophy prioritises ease of maintenance. With only two moving internal components – the piston and the valve – maintenance procedures are minimised and streamlined, resulting in reduced downtime and low associated costs. This simplicity extends to disassembly and reassembly, facilitating swift component replacements. This design nuance significantly contributes to prolonged operational uptime, ensuring that maintenance tasks when required are efficient and effective.

Precise Blow Force

Uncompromising Durability

THOR’s commitment to uncompromising durability is exemplified by the use of premium high-strength heat-treated alloy steel in the manufacturing process of our rock breakers. This alloy steel offers an exceptional combination of tensile strength, hardness, and resistance to wear and abrasion. This not only extends the operational life of the equipment but also ensures optimal performance even under the most demanding working conditions. The alloy’s inherent toughness reduces the risk of fractures and deformations, delivering robustness that resonates across diverse applications.

THOR’s commitment to quality is also reflected in our rust resistant nickel plated bolts, flash chromed pins and bosses as well as top quality industrial painted power cells.

THOR’s heavy duty mounts for skid steers, tractors, loaders, and telehandlers weighing 200 – 250kg are made from 16mm and 20mm plate steel and together with their slanted legs and are the most stable on the market. The mounts are quick and easy to attach and when detached from the host machine and when not in use they stand anchored where left, with no danger of them falling over.

The Advantages of Engineering Excellence

THOR’s advance design yields a multitude of advantages. Our focus on robust materials and engineering precision enhances equipment longevity, minimising replacement cycles.

The synergy between hydraulic and nitrogen driven impact results in unparalleled force, enabling efficient material breakage and excavation, the simplicity of our design translates to minimised maintenance demands, ensuring operational continuity.

With THOR rock breakers and post drivers, you benefit from precise, powerful, and reliable equipment that maximises productivity, reduces costs and stands as a testament to innovative engineering excellence.

Elevate your operations today with THOR Rock Breakers and Post Drivers – where advanced design defies a new standard in construction equipment performance.

Post Driver Attachments for Mini Skid Steer Loaders

(Including Hydraulic, Nitrogen-Assisted, Box, and Silenced Types)

1. PURPOSE

This guide provides detailed technical information on post driver attachments designed for mini skid steer loaders, including their mechanical principles, system design, nitrogen functionality, and maintenance requirements.

It explains how different types of post drivers operate on compact loader systems (typically 400–1000 kg lift capacity), ensuring safe and efficient post driving performance.

Note: Nitrogen filling and charging procedures are excluded and must only be performed by trained service personnel.

2. OVERVIEW

A post driver attachment allows a mini skid steer loader to deliver repetitive, high-energy impact blows for driving posts, stakes, or piles into the ground.

The system converts hydraulic energy from the loader’s auxiliary circuit into mechanical impact energy, often enhanced by nitrogen gas in certain models.

These attachments are compact, efficient, and ideal for fencing, landscaping, farm, or construction applications where maneuverability is essential.

3. SYSTEM FUNCTION

3.1 Operating Principle

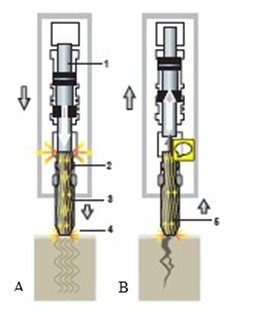

- The mini skid steer’s hydraulic circuit supplies pressurized oil to the post driver.

- The oil flow lifts a piston or striker within the hammer housing.

- In nitrogen-assisted units, a gas chamber compresses as the piston rises.

- When the oil flow reverses or is released, the compressed nitrogen expands, propelling the piston downward at high velocity.

- The piston strikes the driving tool or cup, transferring energy to the post.

4. TYPES OF POST DRIVER ATTACHMENTS

4.1 HYDRAULIC-PERCUSSIVE (NITROGEN-ASSISTED) TYPE

(Most common for mini skid steers)

Description

Hydraulic hammer-style driver with an integrated nitrogen accumulator that stores and releases energy each stroke.

Advantages

Advantages

- High impact energy and blow rate (700–1200 bpm typical).

- Efficient for hardwood posts and compact soils.

- Reduced recoil and smoother operation due to nitrogen damping.

Considerations

Considerations

- Requires periodic nitrogen pressure checks (by a technician).

- Slightly heavier than purely hydraulic models.

Typical Use

Fence posts, gate posts, timber or steel stakes, small piles, solar or farm fencing.

4.2 FULLY HYDRAULIC (OIL-ONLY) TYPE

Description

Simpler design using only hydraulic oil pressure to lift and drop the striker.

No nitrogen chamber is present.

Advantages

Advantages

- Minimal servicing requirements.

- Consistent power when maintained properly.

- Ideal for smaller loaders with lower flow rates.

Limitations

Limitations

- Lower impact frequency.

- Higher vibration transmitted to the skid steer arms.

Typical Use

Light-duty fencing, agricultural and landscaping tasks.

4.3 BOX-TYPE DRIVER (ENCLOSED HOUSING)

Description

A hydraulic-nitrogen post driver enclosed in a heavy-duty box frame, providing protection and vibration isolation.

Used on skid steers and excavators for professional, heavy-duty use.

Advantages

Advantages

- Full protection of internal hammer and seals.

- Very low recoil to the loader arms.

- Quieter and smoother than open-frame designs.

Considerations

Considerations

- Slightly heavier; may require loaders >25 L/min flow.

- Limited visibility near the post due to housing size.

Typical Use

Professional fence-line installation, steel or hardwood posts, continuous heavy use.

4.4 SILENCED-TYPE DRIVER

Description

Similar to box-type, but features an acoustic housing with polyurethane or rubber lining to minimize noise and vibration.

Advantages

Advantages

- Reduces noise levels by 10–15 dB.

- Ideal for urban or residential applications.

- Minimizes operator fatigue.

Considerations

Considerations

- Slightly heavier and requires airflow to prevent overheating.

Typical Use

Residential fencing, equestrian fencing, urban landscaping.

4.5 GRAVITY DROP DRIVER

Description

Mechanical system where hydraulic lift raises a weighted hammer, which then drops under gravity.

Advantages

Advantages

- Simple and low-maintenance.

- Easy to repair in the field.

- No gas or accumulator required.

Limitations

Limitations

- Lower strike frequency.

- Not suitable for compact or rocky ground.

Typical Use

Soft ground fencing, lightweight timber posts.

4.6 VIBRATORY DRIVER

Description

Hydraulic motor spins eccentric weights that generate vertical vibration, oscillating the post into the ground without percussive striking.

Advantages

Advantages

- Low vibration to the loader arms.

- Continuous, smooth post insertion.

- Works well with steel or aluminum posts.

Limitations

Limitations

- Ineffective for thick wooden posts or rock.

- Requires higher hydraulic flow (45–70 L/min).

Typical Use

Guardrail posts, sheet piles, metal posts, solar farm structures.

5. MOUNTING CONFIGURATIONS

| Mount Type | Description | Advantages | Typical Use |

|---|---|---|---|

| Top-Mounted | Attachment mounts vertically on front plate; impact directed straight through loader arms. | Best for deep driving; strong vertical alignment. | Heavy or deep posts, open ground. |

| Side-Mounted | Driver offset to one side of loader for improved line-of-sight and clearance. | Easier visibility, ideal for fence lines and edges. | Boundary fencing, roadside work, tight access. |

Most mini skid steer drivers use top mounting, but side-mounted adapters are available for fencing contractors needing visibility along boundaries.

6. NITROGEN GAS SYSTEM (For Gas-Assisted Models)

6.1 Function Overview

The nitrogen chamber stores compressed gas energy to:

- Boost downward striking power.

- Cushion recoil forces.

- Maintain high blow frequency.

6.2 Components

| Component | Function |

|---|---|

| Accumulator / Gas Chamber | Stores compressed nitrogen for impact stroke. |

| Separator (Piston or Diaphragm) | Prevents hydraulic oil from mixing with nitrogen. |

| Gas Charging Valve | Allows gas pressure measurement (by trained personnel). |

| Dampers & Bushings | Absorb vibration and protect loader arms. |

6.3 System Characteristics

| Parameter | Typical Range | Notes |

|---|---|---|

| Nitrogen Working Pressure | 20–40 bar (290–580 psi) | Depends on hammer size |

| Hydraulic Flow Requirement | 20–45 L/min | Typical for mini skid steers |

| Hydraulic Pressure | 120–180 bar | Loader auxiliary circuit |

| Impact Frequency | 600–1200 bpm | Higher with optimal nitrogen pressure |

Never use air, oxygen, or CO₂ — nitrogen only (99.9% pure).

Nitrogen servicing must only be performed by authorized service technicians.

7. INSPECTION & MAINTENANCE (EXCLUDING GAS FILLING)

7.1 Daily Checks

| Check | Purpose |

|---|---|

| Inspect accumulator housing and seals for oil leaks. | Detect seal wear or gas loss. |

| Ensure dust cap is fitted to gas valve. | Prevent contamination. |

| Check hydraulic hose fittings for leaks. | Prevent pressure loss or damage. |

| Observe blow consistency and sound. | Identify early nitrogen loss. |

| Check mounting pins and brackets. | Prevent vibration-related wear. |

7.2 Periodic Maintenance (Every 250–500 Hours)

| Task | Description |

|---|---|

| Pressure check by authorized technician. | |

| Inspect accumulator for corrosion or deformation. | |

| Check damping bushes and isolators for cracks or wear. | |

| Clean hydraulic couplers and vents. | |

| Inspect mounting plate bolts and bracket integrity. |

7.3 Annual Service

| Task | Description |

|---|---|

| Replace nitrogen-side O-rings and seals. | |

| Check diaphragm/piston separator for damage. | |

| Clean and re-lubricate tool bushings. | |

| Check vibration isolators and replace if needed. | |

| Full nitrogen recharge and performance test. |

8. SAFETY INFORMATION

- Only trained technicians may service nitrogen systems.

- Do not weld, drill, or heat the accumulator or housing.

- Use nitrogen only (N₂, 99.9%) — never air or oxygen.

- Depressurize hydraulics before disconnecting hoses.

- Maintain proper PPE (gloves, eye protection, steel-toe boots).

- Label attachments: “Contains Pressurized Nitrogen.”

- Never operate the post driver without a firmly secured post guide or cup.

9. TROUBLESHOOTING (NITROGEN SYSTEM RELATED)

| Symptom | Probable Cause | Corrective Action |

|---|---|---|

| Weak or inconsistent strikes | Low nitrogen pressure | Check and recharge (qualified service). |

| Harsh recoil / excessive vibration | Overcharged nitrogen | Adjust to manufacturer spec. |

| Oil leak near valve | Damaged diaphragm or O-ring | Replace seals or accumulator. |

| No impact / dull thud | Nitrogen chamber empty | Replace or service accumulator. |

| Excessive arm vibration | Worn isolators or low nitrogen charge | Replace isolators, recharge gas. |

10. STORAGE & TRANSPORT

| Condition | Instruction |

|---|---|

| Short-Term (Under 1 Month) | Store upright, valve cap on, clean tool area. |

| Long-Term (Over 3 Months) | Store indoors (5–25°C). Oil exposed steel. Cycle hydraulics periodically. |

| Transport | Secure upright; protect nitrogen valve; label as “Contains Pressurized Nitrogen.” |

11. MAINTENANCE LOG TEMPLATE

| Date | Technician | Hours | Model | Mount Type | Observations | Action Taken |

|---|---|---|---|---|---|---|

12. SUMMARY

| Category | Details |

|---|---|

| Machine Type | Mini Skid Steer Loader |

| Attachment Types | Hydraulic-Percussive (Gas Assist), Fully Hydraulic, Box-Type, Silenced, Gravity, Vibratory |

| Mounting Options | Top-Mounted, Side-Mounted |

| Gas Type (If Applicable) | Nitrogen (N₂), 99.9% pure |

| Operating Pressure | 20–40 bar (nitrogen); 120–180 bar (hydraulic) |

| Hydraulic Flow Range | 20–45 L/min typical |

| Maintenance Interval | 250–500 hours inspection, annual overhaul |

| Noise Level (Box/Silenced) | 95–110 dB typical |

| Key Benefits | Compact, efficient, powerful, and low recoil system |

| Primary Caution | Nitrogen systems are pressurized — service only by qualified personnel |

Mini skid steer post drivers offer high mobility and efficient performance for fencing, landscaping, and construction applications.

Mini skid steer post drivers offer high mobility and efficient performance for fencing, landscaping, and construction applications.

Hydraulic-nitrogen types deliver the most powerful results, while box and silenced models enhance durability and operator comfort.

Proper inspection, nitrogen integrity, and regular servicing are essential for safe and reliable operation.